What Electronic Components Can Reduce Costs in the PCB Manufacturing Process?

As your one-stop distributor of electronic components, we understand the importance of cost control. Next, we will provide you with detailed information on how to effectively reduce PCB manufacturing costs and enhance the market competitiveness of your products by choosing the right electronic components.

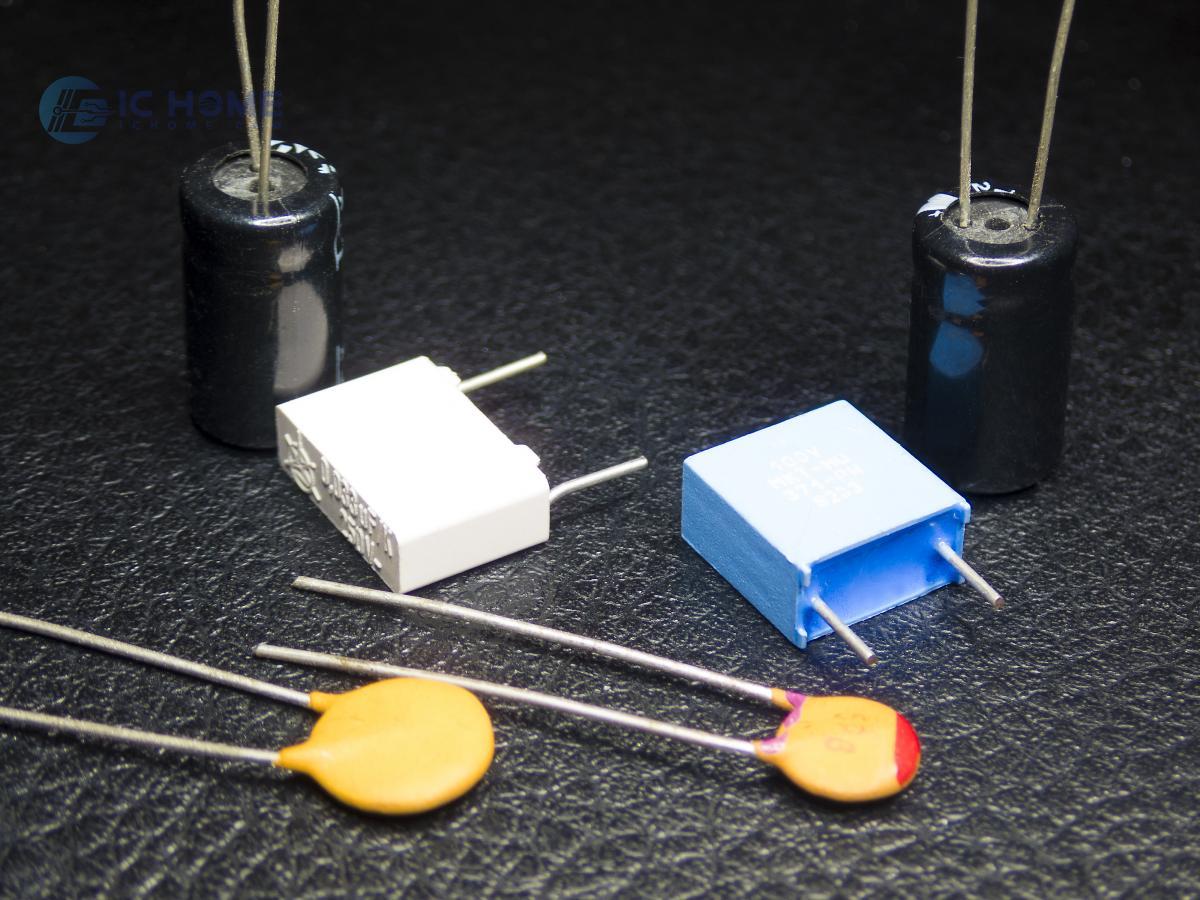

Capacitors are a key component used in any typical PCB layout, and they help to balance functionality and price depending on the type used (film, ceramic or electrolyte).

Ceramic capacitors: with a low ESL/ESR, they are ideal for high frequency applications such as decoupling and noise suppression, making them ideal for general purpose use. When electrolytic capacitors: High capacitance values (e.g. required for power supply filters)

Film capacitors: where accuracy is critical, such as timing circuits and high-fidelity audio applications

Tips for selecting cost-effective capacitors

Evaluate the required capacitance: Consider the minimum capacitance that will satisfy your application, as over-specification of capacitance values can lead to unnecessary expense.

Select Standard Values/Sizes: It is recommended to select standard sizes and values as this will save money as these common components have mass production channels.

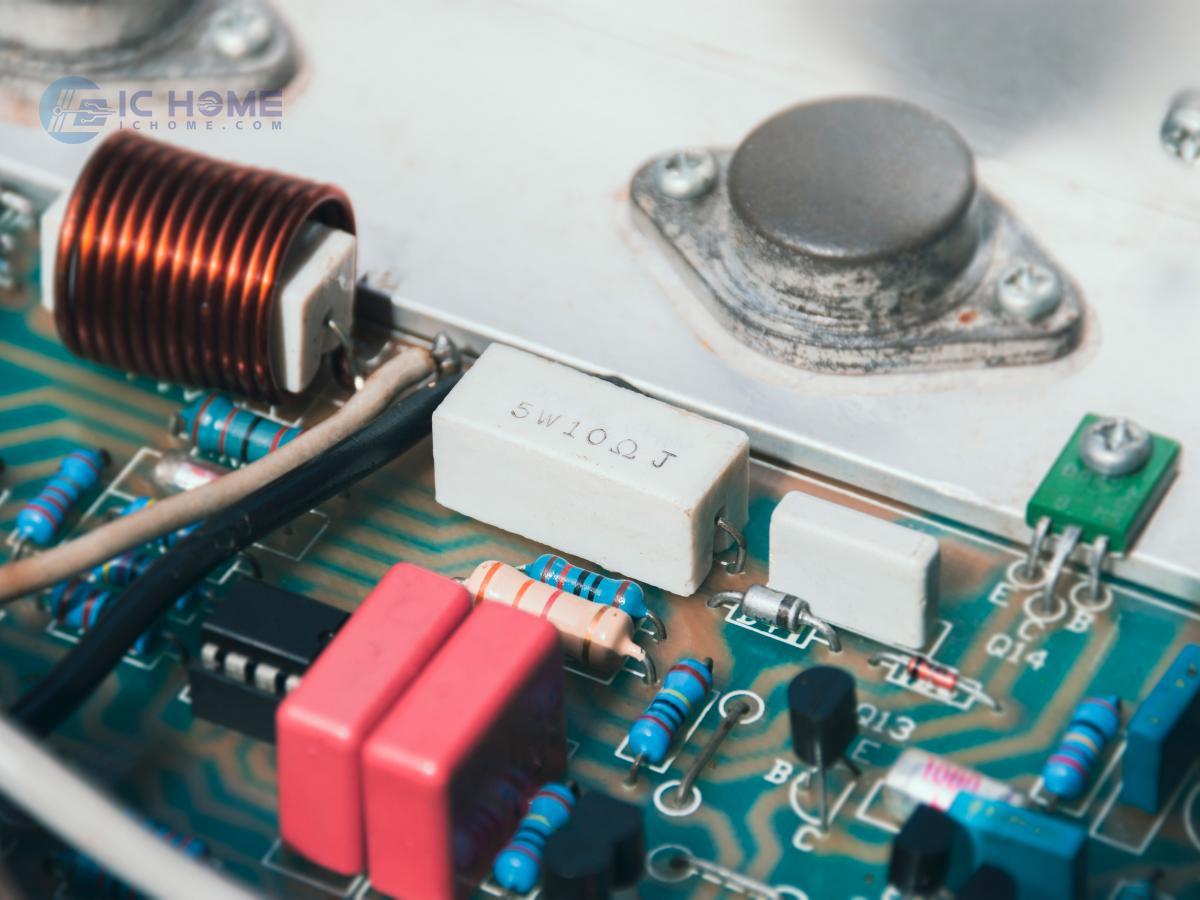

Resistors, like capacitors, are critical in printed circuit boards (PCBs) and the type used can have a significant impact on the cost and performance of a particular design.

Carbon Film Resistors: The cheapest and used in many applications where accuracy is not required.

Thick Film Resistors: Widely used in a variety of applications where the highest precision is not required.

Metal Film Resistors: The highest precision is required.

Thin Film Resistors: Higher stability and high precision applications such as communication equipment or medical devices.

Tips for cost-effective resistor selection

Use standard resistor values: Always try to use common resistor values as these mass-produced products are less expensive.

Carefully consider tolerance requirements: Where very high accuracy is not important, using standard tolerances such as 5% will help to reduce costs.

Microcontrollers integrate memory and peripherals, reducing PCB components and costs. Standard logic ICs are cheaper than MCUs, so it is important to understand the features and trade-offs.

Analog ICs for signal processing require high levels of manufacturing accuracy and are therefore costly. Digital ICs are generally inexpensive and widely used in digital signal processing and control applications.

Application Specific Integrated Circuits (ASICs) are designed specifically for certain applications. This can significantly reduce unit cost, but is limited to high-volume production. Field Programmable Gate Arrays (FPGAs) offer more flexibility; however, they tend to be more expensive for small to medium volume production.

Tips for Cost-Effective IC Selection

Select multifunction ICs: Choosing ICs that combine as many functions as possible on a single chip reduces component count, overall PCB size, and assembly costs.

Evaluate total system cost: Compare the total system cost of using a more expensive, complex IC with that of using multiple inexpensive ICs.

Leverage economies of scale: For products that are sure to enjoy strong demand over time, consider custom ASIC development to maximise lifetime value through economies of scale.

Type and complexity: Basic rows of pins are relatively inexpensive and can be used in many applications. However, most modern designs require more advanced connectors such as USB or HDMI, although they tend to cost more.

Density and Pitch: High density connectors allow more connections per unit area, which can reduce PCB size and cost. However, these types of connectors are relatively expensive due to the high precision required to manufacture them.

Material and Durability: The material composition of a connector affects its price and longevity. Gold-plated connectors offer better conductivity and corrosion resistance than tin-plated connectors, but obviously cost more.

Tips for Cost-Effective Connector Selection

Standardise connector types: Using the same connectors across different product lines can simplify an organisation's inventory management, while also enabling volume buying that attracts volume discounts.

Evaluate the need for connectors: Whenever feasible, solder components directly to the board rather than using additional connectors.

Choose the right quality: always try to buy connectors from a manufacturer with a good reputation for balancing cost and quality to get reliable connectors at an affordable price.

Careful component selection must be combined with efficient layout when it comes to PCB design cost management. By strategically selecting components and using a variety of size reduction techniques, you can achieve significant cost savings without compromising the quality or functionality of the final product.

Whatever electronic components you choose, ICHOME will serve you wholeheartedly.